-

26

Oct

Common Complaints And Feedback From Operators Regarding ECM Performance Or Issues

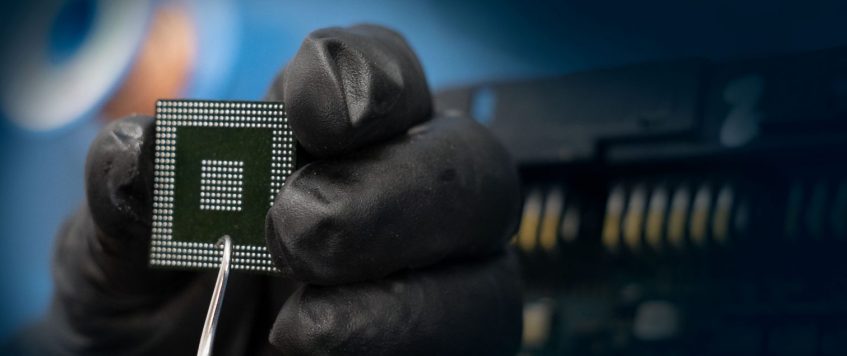

The Engine Control Module (ECM) is a critical component in modern trucks, responsible for monitoring and controlling various engine functions. However, like any electronic system, the ECM is prone to performance issues that can affect the overall functionality of the truck. In this blog post, we will explore the most common ECM performance issues encountered by truck owners and operators. By understanding these issues and their potential causes, truck owners can take preventative measures and ensure the proper functioning of their ECMs. Read on to learn more about common truck ECM performance issues and how to address them.

ECM Performance – What Does It Do?

A truck’s engine control module (ECM) plays a crucial role in the overall functioning of the vehicle. The ECM, also known as the engine control unit (ECU), is essentially the brain of the truck. It is responsible for monitoring and controlling various engine functions to ensure optimal performance and efficiency.

The primary function of the ECM is to regulate the fuel and air mixture that is injected into the engine cylinders during the combustion process. By continuously monitoring factors such as engine speed, temperature, and load, the ECM can adjust the fuel injection timing and quantity to maintain the ideal air-fuel ratio. This not only ensures that the engine operates efficiently, but also helps reduce emissions and improve fuel economy. In addition to fuel management, the ECM also controls other critical engine systems.

It regulates ignition timing, which determines when the spark plugs fire to ignite the air-fuel mixture. It also monitors and adjusts variables such as turbo boost pressure, idle speed, and exhaust gas recirculation (EGR) to optimize engine performance and emissions.

Furthermore, the ECM collects and stores data from various sensors located throughout the truck’s engine and other components. This data can be accessed by technicians using specialized diagnostic tools and software to diagnose and troubleshoot mechanical issues. The ECM also generates fault codes that can help identify specific problems. That makes it an invaluable tool for maintenance and repairs.

What Are Some Common Problems With ECMs?

One common problem that truck ECMs may experience is faulty sensors. Sensors play a crucial role in providing the ECM with accurate data about the engine’s performance and conditions. If a sensor is faulty or damaged, it can provide incorrect information to the ECM, leading to inefficient engine operation and potential performance issues. Regular sensor maintenance and inspections can help prevent sensor malfunctions, and timely sensor replacements should be performed when necessary.

Another problem that can occur with truck ECMs is software glitches or bugs. The ECM’s software is responsible for controlling the engine and ensuring its optimal functioning.

However, software errors can lead to issues such as engine misfires, irregular fuel injection, or even complete engine failure. To mitigate these problems, trucking companies should regularly update their ECMs’ software and ensure that they have access to the latest firmware versions provided by the manufacturer.

Additionally, it is essential to have a professional technician capable of diagnosing and troubleshooting software-related issues. Electrical malfunctions can also affect truck ECMs. Wiring problems, such as loose connections, damaged cables, or short circuits, can disrupt the ECM’s ability to receive and send signals, leading to erratic engine performance or even total engine shutdown.

Employing proper wiring management techniques, such as securing cables and regularly inspecting them for signs of wear or damage, can help prevent electrical malfunctions. Lastly, heat can be a significant factor in ECM malfunctioning. Truck engines produce a significant amount of heat during operation, and if the ECM is not adequately protected or cooled, it can overheat and become damaged. Ensuring proper ventilation and cooling mechanisms for the ECM can help maintain its optimal functioning.

How Do I Get Started?

At Truck ECM, we understand that not everyone is a programming expert. That’s why we’re here to help you with all your truck ECM needs. We have a team of experts who can help you with everything from choosing the right ECM to installing and programming it. We can even help you troubleshoot any problems you might have.

So if you need help with your ECM, don’t hesitate to give us a call. We’re here to help you get the most out of your vehicle to make sure it runs smoothly!